Email us at sales@gambitcorp.com

Call (707)-588-2797

Platinum, silver alloys

Tungsten

Nickel

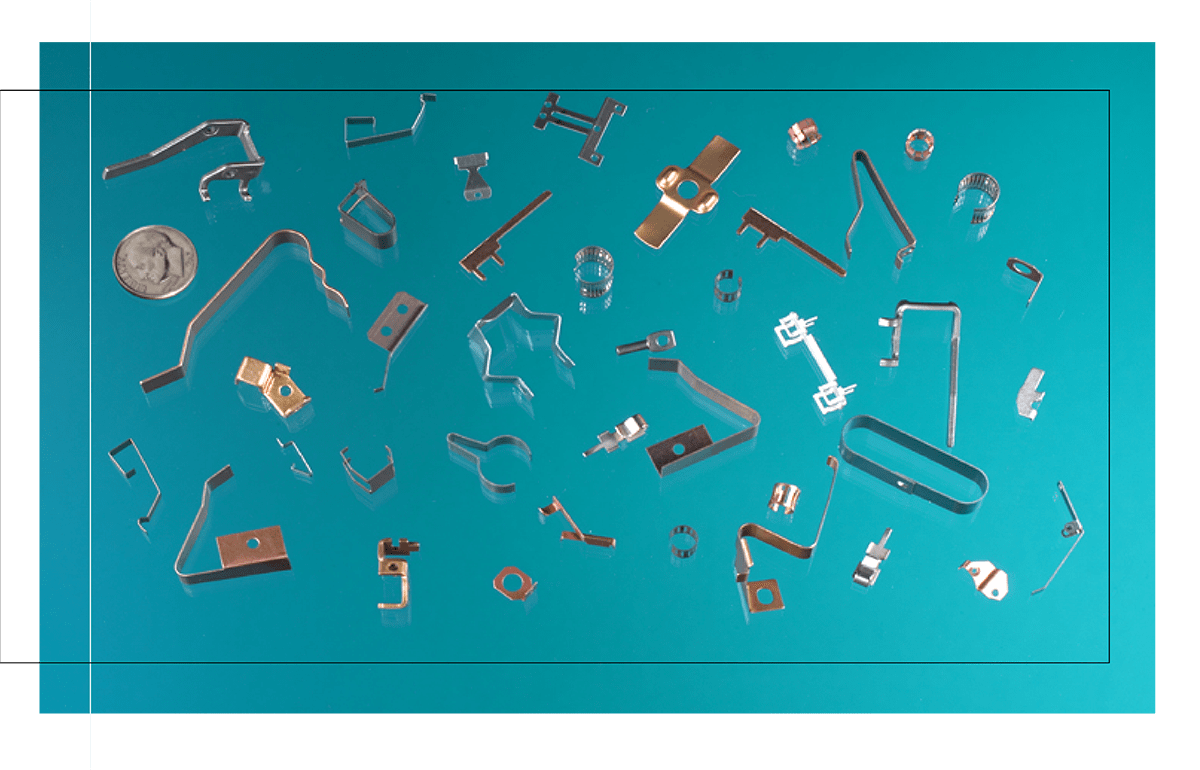

Beryllium copper

Stainless or basic steel

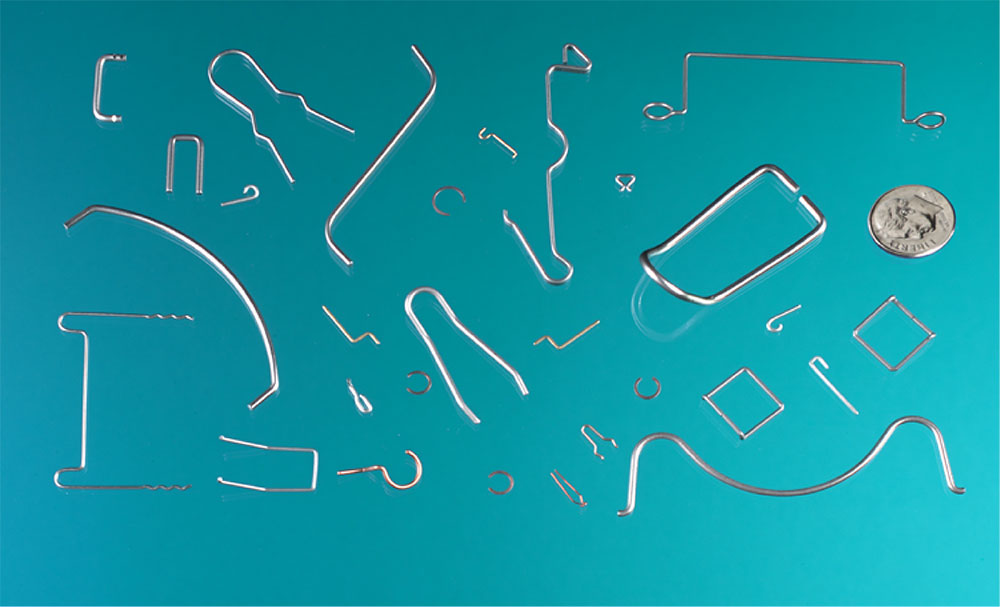

Wire

Cold-roll strip

Diameter .003 - .125"

Length up to 9"

Thickness .001 - .060"

Maximim Width is 1"

Maximim Feed Length 9"

Straight and cut tungsten

Custom molded

Bare print wires

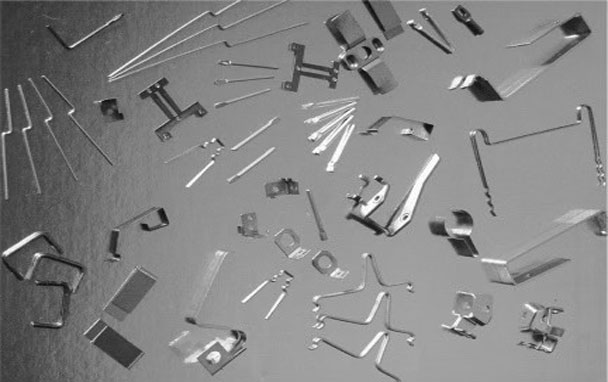

Fourslide and multislide machines can be more economical when producing small springs,

stampings and wireforms, because the traditional die and stamp press method is not required.

Materials can be purchased to finished width, reducing scrap.

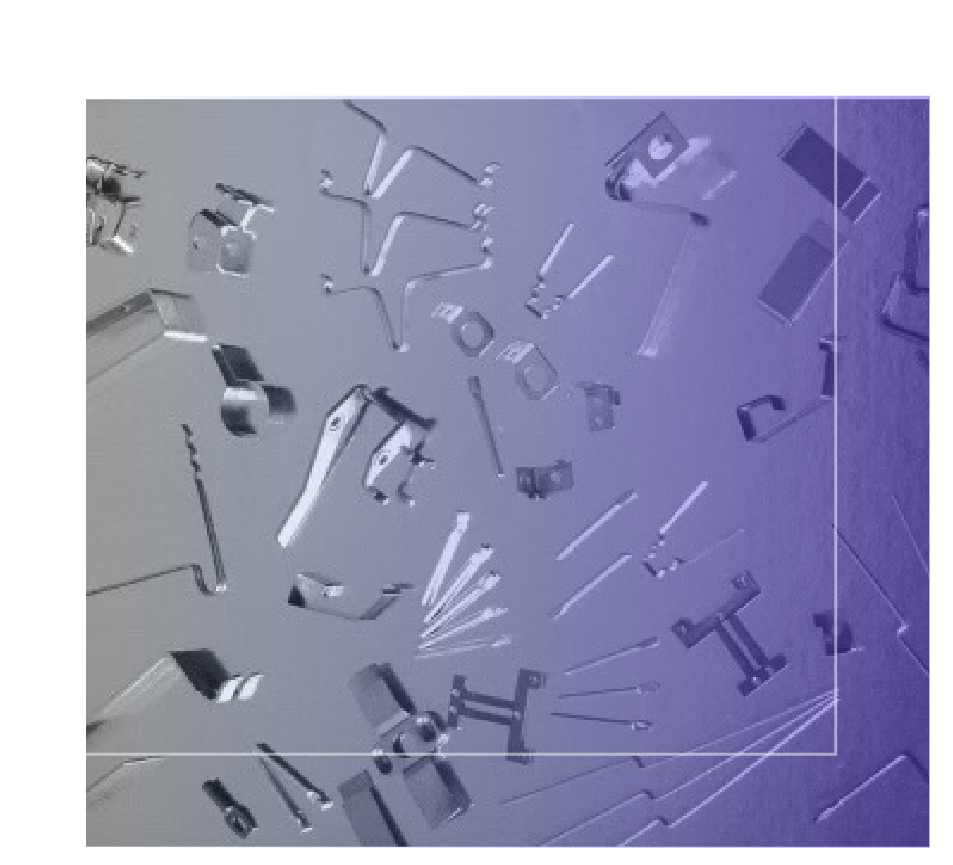

Our fourslide and multislide machines are capable of making many parts from wire or flat

stock. We manufacture very small, intricate parts, which may require bends greater

than 90° or multiple bends and twists. We also produce larger components.